Studies confirm positive ecological balance.

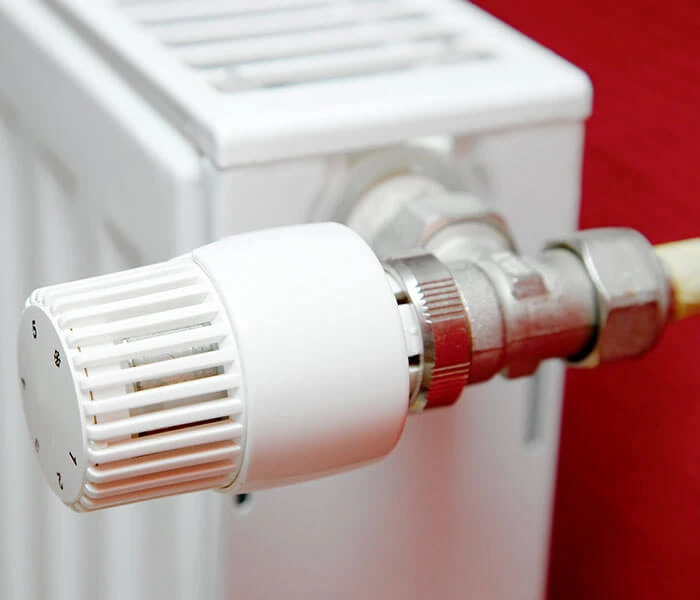

Industrially manufactured products require raw materials and energy for their production. The question of the extent to which they impact the environment is becoming increasingly important for both manufacturers and consumers in the wake of climate change. Technical insulation materials are a special case here, as they save energy over their service life. Even if other products consume less energy and cause less CO2 emissions during their manufacture, FEF and PEF materials can have a better overall ecological balance.

Studies by member companies confirm this. Various CEFEP members carried out analyses of their products over their entire life cycle (Life Cycle Assessment) in accordance with EN 15804. The results show that FEF insulation materials also have a positive impact on the energy balance of buildings thanks to their superior technical properties.